Skip to content

Engineering Mechanics and Refractory Testing for Refining and Petrochemical Industries

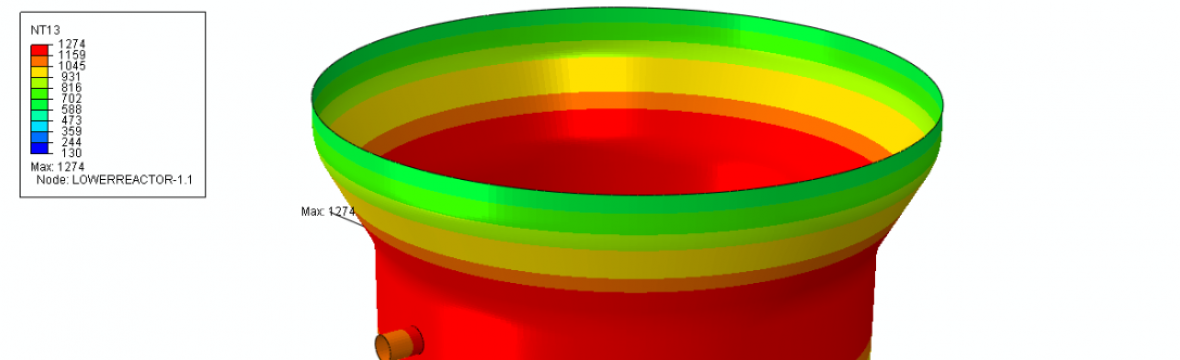

Finite Element Analyses using ABAQUS 2017

- Linear and non-linear (elastic-plastic)

- Thermal and structural

- Pressure boundary

- Vessel, reactor and exchanger details

- Flanges and special piping components

- Bimetallic joints and thermal gradient stresses

- Non-pressure boundary

- Tray support beams and catalyst support grids

- FCC reactor and regenerator internals

- General structural components and machine design

API – 579, Fitness-for-Service Analyses

- General and local thinning

- Vessel, pipe and tank distortions (dents, bulges, out-of-round)

- Cracks

- Fatigue life assessment

- Fatigue crack growth

- Creep life

ASME Boiler and Pressure Vessel Code Analyses

- Section VIII, Divisions 1, 2 and 3

- New construction and re-rating

Refractory Inspection, Troubleshooting and Design

- Emphasis on Fluid Catalytic Cracking Units

- Erosion resistant linings

- Gunned and cast insulating linings

- Refractory testing per API-936

- API-936 Refractory Practitioner Certification: 28449

Pressure Vessel and General Process Unit Mechanical Inspection and Troubleshooting.

Professional Engineer registered in Pennsylvania: PE-054867-E